Quick Answer

Chain surveying relies on a set of simple, manual instruments to measure distances and plot features of relatively small and flat terrains. The most common instruments include chains, tapes, ranging rods, arrows, pegs, cross-staffs, and plumb bobs. Each tool plays a specific role—from marking alignment to ensuring level ground readings—making them essential for foundational surveying work. Despite the rise of digital surveying methods, chain surveying remains valuable for low-budget or educational applications.

- Chain: Main tool for measuring horizontal distances.

- Tape: Used for shorter or more precise measurements.

- Ranging Rods: Ensure straight line alignment between survey points.

- Arrows & Pegs: Used for marking measured positions on the ground.

- Cross-Staff: Helps with drawing perpendicular offsets.

This article explores each instrument in detail—what it is, how it’s used, and why it matters.

Flat terrain doesn’t require high-tech tools. In chain surveying, simplicity and precision go hand-in-hand. A surveyor with just a few basic tools can map a plot with accuracy that’s stood the test of time. But what exactly are those tools—and how do they work together in the field?

Let’s explore it further below.

Chain: The Core Measuring Tool

Chains are the namesake of chain surveying and form the backbone of all distance measurement in the method. There are multiple types of chains, but the metric chain is most commonly used today.

Types of Chains in Surveying

| Chain Type | Length | Use Case |

|---|---|---|

| Metric Chain | 20m or 30m | General surveying |

| Engineer’s Chain | 100 feet | Engineering and construction works |

| Gunter’s Chain | 66 feet | Used historically in land measurement (1 acre = 10 square chains) |

Construction and Use

A chain consists of a series of galvanized mild steel links connected together, each link typically being 20 cm long. Brass handles are fixed at both ends, with tags marking every meter for easy reading. Chains are laid along a straight path between two points, with arrows used to mark ends during long measurements.

Real-World Example

In rural land plot division, metric chains are ideal for marking field boundaries that don’t require ultra-fine accuracy.

Accuracy Considerations

Chains can expand or contract due to temperature and wear. Routine calibration and checking against a standard tape are essential to prevent cumulative errors.

Tapes: For Precision Beyond Chains

Though chains are robust, tapes offer more flexibility and precision, especially over short distances or when obstructions prevent a chain from lying flat.

Types of Tapes

| Tape Type | Material | Flexibility | Accuracy |

|---|---|---|---|

| Linen Tape | Fabric | High | Low (can stretch) |

| Steel Tape | Steel | Medium | High |

| Invar Tape | Invar alloy | Low | Very High (used in geodetic surveys) |

Application in Fieldwork

- Short measurements where chains cannot be laid

- Verification of chain readings

- Measuring around corners or bends

Technical Analogy

Think of a steel tape like a tailor’s measuring tape, but rigid and calibrated to resist deformation. It can be reeled in and out for quick, accurate readings.

Ranging Rods: Aligning the Line of Sight

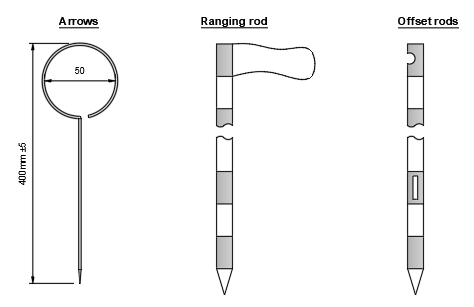

Ranging rods are long, brightly painted poles used to mark survey stations or ensure correct alignment during chaining. Their height (2–3 m) and distinct color bands make them visible over long distances.

How They’re Used

- Placed vertically at endpoints of a line.

- Intermediate rods help align long distances.

- The person at the far end “ranges out” using visual signals.

Practical Scenario

In a 100-meter open field, the surveyor places ranging rods at each end and one midway to maintain a perfectly straight line, avoiding any curvature errors due to terrain undulations.

Material and Visibility

Most ranging rods are made of wood or steel with alternating red and white 1-foot bands, helping visibility even under poor lighting.

Arrows and Pegs: Ground Position Markers

These are simple yet essential tools that serve as ground reference points during measurements.

Arrows

- Material: Hardened steel wires

- Shape: 40 cm long with pointed ends

- Use: Inserted into the ground to mark every full chain length during measurement

Pegs

- Material: Wood, square cross-section

- Length: 15 cm to 50 cm

- Use: Mark permanent survey stations

Comparison Table

| Feature | Arrows | Pegs |

|---|---|---|

| Use | Temporary marking | Permanent marking |

| Material | Steel wire | Wooden block |

| Removal | Frequent | Rare |

Example in Use

During a 300-meter chaining task, a surveyor places arrows every 30 meters and uses pegs to denote station start and end points for later reference.

Cross-Staff and Optical Square: Setting Perpendiculars

Offsets are essential in chain surveying for plotting features that do not lie directly on the survey line. Tools like the cross-staff and optical square make this possible.

Cross-Staff

- Design: Hollow octagonal or cylindrical tube with vertical slits

- Function: Used to sight a right angle from the chain line to a feature

- Placement: Centered over the chain line, rotated until both slits align with the object

Optical Square

- Design: Uses mirrors or prisms to reflect images at 90°

- Accuracy: More precise than a cross-staff

- Field Benefit: Allows sighting perpendicular features without needing to stand over the line directly

Practical Use Case

While measuring a field, the surveyor uses a cross-staff to take a perpendicular measurement to a boundary fence, which is later plotted as an offset on the map.

Plumb Bob: Ensuring Vertical Accuracy

A plumb bob is a pointed weight, usually made of brass or steel, suspended from a string. While simple, it’s vital for ensuring true vertical alignment when transferring or checking points between levels.

How It’s Used

- When measuring from elevated structures or mapping points directly above/below a reference line.

- To ensure a survey point marked on a surface is vertically aligned with a position below.

Example

If a survey station is on a raised platform, a plumb bob is suspended to the ground to mark its precise projection below.

Technical Insight

Due to gravity, a plumb bob always points directly toward the Earth’s center—making it a reliable tool for achieving vertical precision in the absence of digital leveling tools.

Line Ranger: Finding Midpoints Accurately

The line ranger is a small optical device used to find the intermediate point between two ranging rods.

Construction

- Comprises two prisms arranged so the user sees images of both rods simultaneously.

- When the reflections of the rods align, the user knows they are precisely between the two.

Application

- Saves time and improves accuracy in long-distance ranging.

- Particularly helpful when only one person is available to set out intermediate points.

Field Scenario

On a 100-meter chaining task, a surveyor alone uses the line ranger to set a midpoint station without needing assistance.

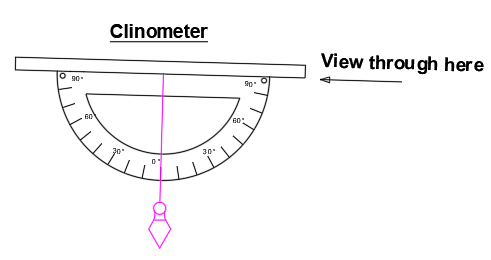

Clinometer and Abney Level: Measuring Slopes

Although chain surveying is mostly used on level ground, occasionally the terrain may have a slight incline. In such cases, a clinometer or Abney level helps measure the angle of slope.

Abney Level Features

- A sighting tube, spirit level, and vernier scale.

- Used to measure vertical angles or gradients.

- More accurate than a basic clinometer.

Use Case

When chaining across an inclined pathway, a clinometer helps calculate the slope. The horizontal equivalent of the distance can then be computed to correct for elevation errors.

Why It Matters

Slopes, even mild ones, can distort chain lengths if not corrected. A 3° slope over 100m can result in ~0.14m of error—enough to compromise high-accuracy mapping.

Mallet: For Peg Installation

The mallet is a heavy hammer used to drive wooden pegs into the ground. Though often overlooked, it’s crucial when marking permanent stations or boundary points.

Details

- Typically made of wood with a cylindrical or rectangular head.

- Used with pegs to ensure they are flush and secure in the ground.

Practical Role

Without a proper mallet, pegs may not seat firmly, leading to position shifts due to weather or accidental contact.

Whites or Laths: Enhancing Visibility

“Whites” or laths are narrow, white-painted wooden strips used to mark lines, especially on grassy or uneven ground.

Benefits

- Improve visibility in long-range chaining.

- Used to demarcate straight paths or guide alignments when terrain obscures ground-level markers.

Where They Shine

In overgrown or visually cluttered fields, whites can guide the chaining process visually from a distance, preventing misalignment.

Comparison Table: Chain Survey Instruments at a Glance

| Instrument | Primary Use | Portability | Accuracy | Notes |

|---|---|---|---|---|

| Chain | Horizontal distance measurement | Medium | Moderate | Durable but needs calibration |

| Tape | Short/precise measurement | High | High | Prone to sag/stretch over time |

| Ranging Rod | Line alignment | High | Visual only | Essential for long measurements |

| Arrow | Chain length marking | High | N/A | Easy to lose if ground is soft |

| Peg | Station marking | Medium | N/A | Semi-permanent markers |

| Cross-Staff | Perpendiculars/offsets | High | Moderate | Basic tool, best for flat terrain |

| Optical Square | Right angles | High | High | More precise than cross-staff |

| Plumb Bob | Vertical projection | High | High | Gravity-dependent |

| Line Ranger | Midpoint location | High | High | Saves time during chaining |

| Abney Level | Measuring slopes | Medium | Very High | Requires user training |

| Mallet | Driving pegs | Low | N/A | Simple but essential |

| Whites/Laths | Visibility enhancement | High | Visual aid | Optional but effective in field |

Importance of Calibration and Maintenance

Even though the instruments used in chain surveying are manual, their precision depends heavily on proper maintenance and periodic calibration.

Common Calibration Issues

- Chain elongation due to stretching of links.

- Tape warping or fading from sun and moisture exposure.

- Optical misalignment in optical squares or line rangers.

- Bent arrows that no longer point accurately.

- Worn pegs that can’t be driven securely.

Best Practices

- Compare chains and tapes against a standard reference line every 3–6 months.

- Store tapes in a dry, coiled position.

- Regularly clean and repaint ranging rods, laths, and whites to retain visibility.

- Replace worn or corroded tools instead of continuing with inaccurate readings.

Tip from the Field

A small calibration error over several chained lines can cause compounding errors large enough to misrepresent a boundary—especially in land legalities. Always double-check critical lengths.

How to Choose the Right Instruments for Your Survey

Not every job requires every tool. Selecting the right combination depends on terrain, precision, and survey goals.

For Flat, Open Ground

- Metric chain (30m)

- Arrows

- Ranging rods

- Cross-staff

For Rough Terrain

- Steel tape (to handle bending)

- Clinometer or Abney level

- Plumb bob

For High-Precision Work

- Steel or Invar tape

- Optical square

- Line ranger

- Frequent recalibration

Budget vs. Accuracy Trade-Off

| Scenario | Recommended Tools | Justification |

|---|---|---|

| Educational Fieldwork | Chain, tape, arrows, rods | Inexpensive, easy to demonstrate |

| Legal Land Survey | Steel tape, Abney level, optical square | Higher accuracy needed for documentation |

| Construction Site Layout | Engineer’s chain, pegs, mallet | Quick, durable, semi-permanent markings |

Benefits of Using Traditional Chain Survey Tools

Despite the digital evolution of surveying (like total stations and GPS), chain surveying tools still have unique advantages.

Key Benefits

- Cost-Effective: Perfect for small-scale or budget-limited projects.

- Easy to Train: New surveyors can understand the basics without technical background.

- No Power Needed: Fieldwork isn’t stalled by dead batteries or software issues.

- Portable: Most tools fit into a compact kit.

Use in Developing Regions

In areas without access to modern instruments or skilled technicians, chain surveying remains a reliable fallback, particularly for rural land partitioning, irrigation planning, and local construction.

Learning Curve Advantage

Chain surveying tools provide hands-on experience with fundamental concepts like alignment, offsets, and measurement correction—which are still applicable in digital surveying.

Limitations and Errors in Chain Surveying

Every technique has limitations, and understanding them is vital to reduce mistakes.

Limitations

- Not suitable for hilly or forested terrain.

- Chain measurements can’t handle curves or overgrown features easily.

- Time-consuming over large distances.

- Accuracy limited to 1 in 250 to 1 in 500 (compared to 1 in 10,000 for EDM).

Common Sources of Error

| Error Type | Cause | Prevention |

|---|---|---|

| Cumulative Error | Link wear, tape sag | Calibrate regularly |

| Alignment Error | Misplaced ranging rods | Use line ranger or experienced assistant |

| Slope Error | Not correcting for elevation changes | Use clinometer or Abney level |

| Temperature Effects | Steel expansion/contraction | Measure during mild weather, apply factors |

| Human Error | Poor alignment, misreading | Cross-check readings and use experienced team |

Example: Slope Correction

If a chain measures 100m up a 5° slope, the horizontal distance is:

Horizontal = 100 × cos(5°) ≈ 99.6m

Neglecting this leads to a 0.4m error per line, which can distort map scaling significantly over multiple stations.

Expert Tips to Remember

- Calibrate chains and tapes regularly to maintain accuracy in field measurements.

- Use optical tools like line rangers and optical squares for improved precision over long distances or when working alone.

- Always correct for slope using a clinometer when surveying uneven ground to avoid compounding errors.

- Store instruments properly to prevent rust, bending, or stretching—especially steel tapes and chains.

- Train with manual instruments first to build foundational skills before progressing to digital surveying methods.

FAQs

What are the basic instruments used in chain surveying?

The fundamental instruments include chains (typically metric), measuring tapes, ranging rods, arrows, pegs, plumb bobs, and cross-staffs.

Why is a ranging rod used in chain surveying?

A ranging rod ensures proper alignment of survey lines. It’s placed vertically at endpoints or intermediate points for visual guidance during chaining.

What is the function of a cross-staff in surveying?

A cross-staff is used to draw perpendicular lines (offsets) from the survey line to any nearby feature that needs to be recorded on the survey map.

How do you maintain a surveying chain?

Clean and dry the chain after each use, check it periodically against a standard measurement, and replace any damaged or stretched links.

What is the difference between a chain and a tape in surveying?

Chains are composed of metal links and used for general measurements. Tapes (steel or cloth) are more flexible and accurate, especially over short distances or in uneven terrain.

Can chain surveying be done on uneven ground?

While not ideal, chain surveying on uneven ground is possible with corrections. Tools like clinometers and Abney levels help adjust measurements for slope.

What is an arrow used for in chain surveying?

Arrows are thin steel markers placed into the ground at regular chain intervals to track progress and ensure accurate chaining over longer distances.

How do you correct errors due to slopes in chain surveying?

Measure the slope angle with a clinometer, then calculate the horizontal distance using trigonometry (Horizontal = Measured Length × cos(angle)).

Why are pegs important in surveying?

Pegs are used to mark key points like the start or end of survey lines. They serve as semi-permanent markers, especially for future reference.

What are the limitations of chain surveying?

It’s not suitable for steep, forested, or very large areas. It’s also less accurate compared to modern tools and requires good weather and lighting conditions.

Conclusion

Chain surveying remains a foundational method in the world of land measurement. While simple in its tools, the process demands precision, attention to detail, and good field practices. Whether you’re mapping a rural property or teaching surveying fundamentals, the instruments used—chains, tapes, rods, arrows, and more—work together to deliver reliable results.

Understanding their function, calibration, and proper use can make a significant difference in survey accuracy. Even in the age of GPS and total stations, these manual tools continue to serve a valuable role in education, field validation, and low-budget projects.

Key Takeaways

- Chain surveying uses basic tools like chains, tapes, ranging rods, pegs, and cross-staffs.

- Proper calibration and care of instruments are essential for accuracy.

- Tools like clinometers and optical squares enhance precision, especially on sloped terrain.

- Despite its simplicity, chain surveying is still relevant for specific use cases.

- Understanding how each instrument works helps build strong surveying fundamentals.