Rapid Hardening Cement (RHC) has emerged as a revolutionary solution in the world of construction. With its exceptional properties and fast-setting characteristics, RHC offers numerous advantages over conventional cement types. In this article, we will explore the fascinating world of Rapid Hardening Cement, its applications, and the benefits it brings to construction projects.

What is Rapid hardening cement (RHC)?

Rapid hardening cement gains high strength in a short time. Generally, the strength developed by OPC in 7 days is the same as achieved in 3 days by rapid hardening cement. Rapid-hardening cement is also known as high early-strength Portland cement.

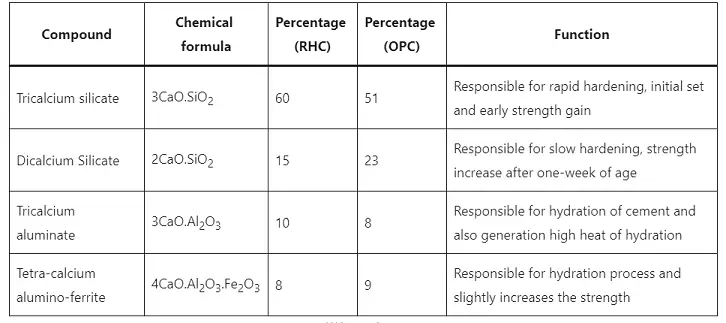

The RHC attains early strength due to the higher fineness (specific area of more than 3250 sq. cm per gram) and higher tricalcium silicate content and lower dicalcium silicate content.

How Rapid Hardening Cement Works

The secret behind the rapid setting of this cement lies in its composition. Rapid Hardening Cement is manufactured by finely grinding clinker with a higher percentage of tri-calcium silicate (C3S) and a small amount of gypsum. This combination accelerates the hydration process, leading to faster strength development.

Factors Affecting the Setting Time of Rapid Hardening Cement

The setting time of Rapid Hardening Cement can vary based on several factors, including:

- Temperature: Higher temperatures generally lead to faster setting, while colder temperatures can slow down the setting process.

- Water-Cement Ratio: The water-cement ratio affects the rate of hydration and, consequently, the setting time.

- Cement Fineness: Finer cement particles can contribute to quicker setting due to increased surface area available for hydration.

- Chemical Additives: The use of chemical additives can modify the setting time and enhance specific properties of the cement.

Chemical Composition of Rapid Hardening Cement(RHC)

Generally, RHC contains the following chemical compounds in proportion.

Manufacture of Rapid Hardening Cement(RHC):

The RHC is manufactured by the dry process of cement manufacture. At first, the calcareous and argillaceous materials are mixed together. Then the mixture is burned at a clinkering temperature. After that the burned we ground the burned clinker to the specified fineness. No other ingredients other than gypsum, water, or both, will be added after burning.

Properties of Rapid Hardening Cement(RHC):

Physical Requirement of RHC:

- Within 3 days RHC obtains 7 days of the strength of OPC with the same water-cement ratio.

- The minimum fineness of RHC (specific surface) is 325 m²/kg.

- The initial setting time is less than 30 mins.

- The final setting time is not more than 600mins.

If the cement shows false, the ratio of 5 min’s final penetration to the 20 sec’s penetration shall not be less than 50%. - Maximum soundness of RHC by Le – Chatlier’s is 10mm. The maximum soundness of RHC by Autoclave is 0.8%.

The steps followed when RHC fails to follow any or both of the above requirements are-

- An aerated sample is prepared for further testing in respect of each failure.

- The aeration is done by spreading out the sample to a depth of 75 mm at a relative humidity of 50-80% for 7 days.

- The expansion of so aerated cement shall not be more than 5 mm in Le – Chatlier’s test and 0.6% in the Autoclave test respectively.

- For determining the compressive strength of RHC at least three mortar cubes are prepared. The area of each face of the cubes is about 50 sq. cm. The mortar for the cube test is composed of 1 part of cement and 3 parts of sand(conforming IS 650:1966) by mass. The water percentage is (P+3.0)% by the combined mass of cement and sand.

The compressive strength achieved thus is- - in 24hrs ± 30 mins not less than 16MPa,

- in 72 hrs ± 60 mins not less than 27 MPa.

∗NOTE– P is the percentage of water needed to obtain a paste of standard consistency.

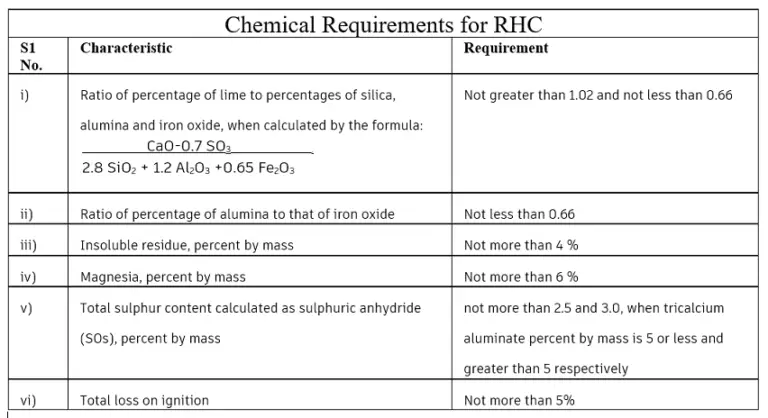

Chemical Requirements of RHC:

The tri-calcium aluminate content is calculated by the formula:

![]()

In the case of reactive aggregates, the use of cement with alkali content below 0.6 percent is recommended. Where, however, such cement is not available, the use of Portland pozzolana cement or cement pozzolanic admixture is recommended.

The total chloride content in cement shall not exceed 0.05 percent by mass for cement used in prestressed concrete structures and long-span reinforced concrete structures.

Applications of Rapid Hardening Cement

Rapid Hardening Cement finds extensive use in a wide range of construction applications, including:

- Road Repairs: Its quick setting properties make it ideal for rapid road repairs, minimizing traffic disruptions.

- Prefabricated Structures: The fast setting time of this cement allows for efficient production and assembly of prefabricated components.

- Emergency Repairs: Rapid Hardening Cement is commonly used for emergency repairs, ensuring immediate structural stability.

- Underwater Concreting: With its ability to set underwater, this cement is suitable for marine applications and projects involving water bodies.

- Cold Weather Construction: Its fast setting nature makes it an excellent choice for construction in cold weather conditions.

Advantages of Rapid Hardening Cement

Using Rapid Hardening Cement offers numerous advantages, making it a preferred choice for time-sensitive projects. Some key benefits include:

- Reduced Construction Time: The rapid setting time of this cement allows for faster construction progress, saving valuable time.

- Early Strength Gain: Rapid Hardening Cement achieves high early strength, enabling early removal of formwork and quicker project completion.

- Increased Durability: The higher strength attained by this cement contributes to the long-term durability of structures.

- Improved Bonding: Rapid Hardening Cement exhibits excellent bonding properties, enhancing the overall integrity of the construction.

- Suitable for All Weather Conditions: Whether it’s hot or cold, Rapid Hardening Cement performs well in various weather conditions, providing flexibility in construction scheduling.

Disadvantages of Rapid Hardening Cement

- The RHC releases a huge amount of heat which causes shrinkage cracks in the structure. Hence, it should not be used in structures in contact with water and water retaining structures.

- The storage of RHC is very challenging. As RHC hardens quickly in the presence of a very little amount of moisture, therefore, it needs quite a dry place storage.

- The Rapid Hardening Cement’s (RHC) cost is also higher than OPC and PPC.

- Any very large concreting structures should not be built with this type of cement. As it liberates a large amount of heat, it can create crakes in the constructed structure.

Comparison with Ordinary Portland Cement

While Rapid Hardening Cement shares similarities with Ordinary Portland Cement (OPC), it has distinct advantages that set it apart. Here are some key differences:

- Setting Time: Rapid Hardening Cement offers significantly shorter setting times compared to OPC, allowing for faster project completion.

- Early Strength: Rapid Hardening Cement achieves higher early strength, ensuring structural stability at an earlier stage.

- Cost: Although slightly more expensive than OPC, the time saved during construction can offset the overall project costs.

Tips for Using Rapid Hardening Cement

To ensure the best results when working with Rapid Hardening Cement, consider the following tips:

- Plan Accordingly: Due to its rapid setting nature, proper planning and organization are crucial before starting any construction activity.

- Optimal Mixing: Follow the manufacturer’s guidelines for the water-cement ratio to achieve the desired consistency and strength.

- Controlled Pouring: Avoid delays during pouring and make sure to place the cement mixture promptly after mixing.

- Curing and Moisture: Proper curing is essential for the development of strength. Maintain the required moisture levels during the initial stages of setting.

Precautions while Using Rapid Hardening Cement

While Rapid Hardening Cement offers many benefits, it is essential to take certain precautions during its usage:

- Protective Gear: Wear appropriate protective clothing, gloves, and goggles to avoid contact with cement dust or skin irritation.

- Avoid Overmixing: Excessive mixing can accelerate the setting time further, leading to difficulties in handling and placing the cement.

- Temperature Considerations: In hot weather conditions, take measures to prevent the rapid drying of the cement by using shade or damp coverings.

Extra Rapid Hardening Cement

Extra-Rapid hardening cement is produced by adding 3% of calcium chloride to the rapid-hardening cement. Extra rapid hardening cement gives 25% more strength than rapid hardening cement in 2 days and 10-20% higher in 7 days.

Advantages of extra rapid hardening cement (EHRC)

- The setting time for EHRC is extremely quick, and it quickly reaches a high strength. This makes it perfect for uses like precast concrete manufacturing and emergency repairs when rapid setting and great strength are required.

- The quick setting time of EHRC significantly minimizes curing time, allowing the project to be placed into operation considerably sooner than with other forms of cement.

- Extra rapid hardening cement is durable and resistant to chemical attack, making it suitable for harsh environments.

- The quick strength gain of extra rapid hardening cement lowers the possibility of shrinkage cracking, which might occur while concrete is curing and shrinking.

- Because of its outstanding workability and ease of mixing and placement, extra rapid hardening cement is suited for use in precast concrete production and other applications requiring quick and efficient installation.

FAQ-Ingredients of Cement:

What is the difference between quick setting cement and rapid hardening cement?

Rapid hardening cement should not be confused with quick setting cement. While quick setting cement only sets rapidly, its strength-gain rate is comparable to that of regular Portland cement, rapid hardening cement develops at a faster pace.

What is the difference between rapid hardening cement and ordinary Portland cement?

Rapid Hardening Cement sets much faster than Ordinary Portland Cement and achieves higher early strength, making it suitable for time-critical projects.

Can rapid hardening cement be used for all construction projects?

Rapid Hardening Cement can be used for a wide range of construction projects, particularly those that require quick turnaround times or have time constraints.

How long does rapid hardening cement take to set?

The setting time of Rapid Hardening Cement can vary depending on factors such as temperature and water-cement ratio. Generally, it sets within a few hours.

Is rapid hardening cement more expensive than ordinary cement?

Yes, Rapid Hardening Cement is slightly more expensive than Ordinary Portland Cement due to its specialized properties and manufacturing process.

Can rapid hardening cement be mixed with other types of cement?

Yes, Rapid Hardening Cement can be mixed with other types of cement to achieve specific performance requirements and desired setting times.

Does rapid hardening cement have higher strength than ordinary cement?

Yes, Rapid Hardening Cement achieves higher early strength compared to ordinary cement, which can contribute to the overall durability of the structure.

What are the precautions to take while using rapid hardening cement?

Some precautions include wearing protective gear, avoiding overmixing, and ensuring appropriate curing and moisture levels during the setting process.

Can rapid hardening cement be used in cold weather conditions?

Yes, Rapid Hardening Cement performs well in cold weather conditions, making it suitable for construction projects in such environments.

Is rapid hardening cement suitable for underwater applications?

Yes, Rapid Hardening Cement can set and gain strength underwater, making it suitable for various underwater construction applications.

Are there any alternatives to rapid hardening cement?

Yes, some alternatives to Rapid Hardening Cement include accelerated-setting admixtures or using a combination of Ordinary Portland Cement and additives.

Conclusion

Rapid Hardening Cement offers a swift and efficient solution for construction projects that require shorter setting times and higher early strength. With its numerous advantages and diverse applications, it has become a go-to choice for time-critical projects, emergency repairs, and challenging construction environments. By embracing the benefits of Rapid Hardening Cement, builders and contractors can enhance productivity, reduce construction time, and deliver durable structures that stand the test of time.