In the world of surveying, EDM (Electronic Distance Measurement) technology has revolutionized the way distances are measured. Traditional methods, while effective, were often time-consuming and less precise. EDM technology has stepped in to offer a faster, more accurate alternative. But what exactly is EDM in surveying, and how can it benefit your projects? This article delves into these questions, providing a comprehensive overview of EDM technology, its advantages, and why it’s become an essential tool for modern surveyors.

What is EDM in surveying?

Electronic Distance Measurement (EDM) is a technology used to measure distances between two points using electronic equipment. Unlike traditional tape measures or optical instruments, EDM devices use electromagnetic waves, such as laser or infrared beams, to determine distances.

Why is EDM Important in Surveying?

EDM technology has become crucial in surveying because it offers significant advantages over older methods. It provides faster measurements, increased accuracy, and the ability to work in challenging environments where traditional methods might fail.

Electromagnetic Distance measuring methods:

There are three distance measuring methods which are as follows:

- Direct distance measurement method (DDM)- Small distances (less than 15 m) are measured with the help of a chain or tape. This method is not suitable for uneven terrains.

- Optical distance measurement method (ODM)- This method covers the limitation of the above method. Different telemetric instruments are adopted in this method. This method is suitable for a distance range of 15-150m. The degree of accuracy attained in this method is 1:1000 to 1:10000.

- The electromagnetic distance measurement method (EDM) is suitable for a distance range of up to 100km. The degree of accuracy attained in this method is up to 1:100000.

Principles of EDM in surveying:

Two distance measuring methods are generally adopted for EDM in surveying.

- Pulse method: The principle of this method depends on the concept that distance traveled is the product of velocity and time. In this method, a short, intensive pulse of radiation is sent out toward a reflector. The reflector then returns it back to the receiver along a parallel path. The distance is calculated by multiplying the velocity of the signal by the time it took to return to the receiver.

- Phase difference method- The basic principle of this method is to measure the phase difference between the transmitted and received signals of infrared, light, or microwave. In this method, the electromagnetic waves are sent out to a retroreflector. Then this retroreflector instantly returns those waves to the transmitter. Now the distance is measured by comparing the phase shift between the transmitted and received signals.

What are the basic functions of the EDM instrument?

The basic functions of an EDM instrument are as follows:

1. Generation and measurement of the carrier wave and its frequencies.

2. The carrier wave’s modulation and demodulation.

3. Determination of the phase difference between the transmitted and received waves

How does EDM work?

EDM instruments work by sending a signal (like a laser beam) from the device to a target point. The signal reflects off the target and returns to the EDM instrument. The device calculates the distance based on the time it took for the signal to travel to the target and back. This process allows for highly accurate distance measurements over various terrains and conditions.

1. The Basic Principle:

- At its core, EDM relies on the principle of measuring the time it takes for a signal to travel from the instrument to a target and back. This signal can be in the form of electromagnetic waves or laser pulses.

2. Emitting Signals:

- In EDM instruments, a transmitter emits a signal towards a specific target point. This signal can be in the form of microwaves or infrared laser beams, depending on the type of EDM instrument being used.

3. Reflecting the Signal:

- The signal hits the target, and ideally, the target reflects the signal back toward the EDM instrument. This is why reflective prisms are commonly used as surveying targets.

4. Measuring Time:

- The EDM instrument precisely measures the time it takes for the emitted signal to travel to the target and return. This time measurement is incredibly accurate, often down to a fraction of a nanosecond.

5. Calculating Distance:

- Using the measured time and the known speed of light (in the case of laser-based EDM) or the speed of electromagnetic waves (in microwave-based EDM), the instrument calculates the distance to the target. The formula is simple: Distance = Speed × Time.

6. Compensation for Environmental Factors:

- To ensure accuracy, modern EDM instruments account for environmental factors that can affect the speed of the signal. These factors may include temperature, air pressure, and humidity.

7. Displaying the Result:

- The calculated distance is typically displayed on the instrument’s screen, providing surveyors with a precise measurement.

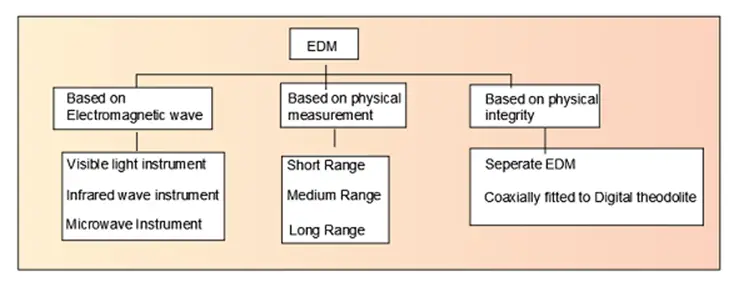

What are the different types of EDM instruments?

The instruments generally classified in EDM in surveying are as follows.

Based on the Electromagnetic wave used

- Visible light instrument: Can operate up to a range of 25 km with an accuracy of ± 10 mm o ±2 mm/ km.

- Infrared waves instrument: Can operate up to a range of 2-5 km.

- Microwave instrument: Can operate up to a range of 25-80- km with an accuracy of ± 15 mm o ±5 mm/ km.

Based on the Physical measurement

- Short-range: less than 5 km of distances are measured.

- Medium range: up to 100km of distances are measured.

- Long-range: more than 100km of distances are measured.

Based on the Physical Integrity

- Separate EDM

- Coaxially fitted with Digital Theodolite

What are the benefits of using EDM in surveying?

Electronic Distance Measurement (EDM) technology has transformed the field of surveying, offering numerous advantages over traditional surveying methods. Here are the key benefits of using EDM in surveying:

1. Accuracy and Precision: EDM instruments provide highly accurate distance measurements, often with sub-millimeter precision. This level of accuracy is crucial for tasks like land boundary determination, construction layout, and mapping.

2. Speed and Efficiency: EDM significantly reduces the time required to measure distances between points. Surveyors can quickly gather data, which translates to increased efficiency and shorter project timelines.

3. Long-Range Measurements: EDM technology allows surveyors to measure distances over long ranges, often exceeding several kilometers. This capability is invaluable for large-scale projects, such as highway construction and geological surveys.

4. Non-Invasive: Unlike traditional methods that may require physical contact with points or obstacles, EDM is non-invasive. Surveyors can measure distances without disturbing the environment or structures, reducing the risk of damage.

5. Reduced Labor: EDM instruments require fewer personnel to operate compared to traditional surveying methods. This reduction in labor costs can lead to cost-effective surveying projects.

6. Enhanced Safety: Surveyors can measure distances from a safe distance, eliminating the need to access hazardous or hard-to-reach locations. This enhances safety on construction sites and in challenging terrain.

7. 3D Coordinate Determination: EDM technology can provide three-dimensional coordinates by taking multiple measurements from different positions or angles. This is essential for creating detailed topographic maps and models.

8. Data Integration: EDM instruments often come equipped with electronic data recording capabilities. Survey data can be seamlessly integrated into computer-aided design (CAD) software, Geographic Information Systems (GIS), and other digital tools for analysis and visualization.

9. Environmental Adaptability: Modern EDM instruments are equipped with environmental sensors that compensate for factors like temperature, humidity, and air pressure, ensuring accurate measurements under varying conditions.

10. Remote Monitoring: – Some EDM systems can be remotely operated, allowing surveyors to collect data without being physically present at the measurement site. This is particularly useful for monitoring changes in structures or natural features over time.

11. Increased Surveying Range: – EDM technology can survey beyond line-of-sight, making it suitable for tasks like tunnel and underground mining surveys where direct measurements are challenging.

12. Real-Time Feedback: – Many EDM instruments provide real-time feedback on measurements, allowing surveyors to quickly identify and correct errors, ensuring data accuracy on-site.

13. Cost Savings: – The speed, accuracy, and efficiency of EDM can lead to cost savings on surveying projects. Reduced labor, quicker data collection, and improved accuracy can translate into lower overall project costs.

14. Versatility: – EDM instruments are versatile and adaptable to various surveying applications, including topographic mapping, construction layout, boundary surveys, and geodetic measurements.

Uses of Electronic Distance Measurement (EDM) in Surveying

Electronic Distance Measurement (EDM) technology has a wide range of applications in the field of surveying, offering precise and efficient solutions for various tasks. Here are some of the key uses of EDM in surveying:

1. Land Boundary Surveys: EDM is commonly used to determine property boundaries accurately. Surveyors can measure distances between boundary markers or reference points, ensuring the correct demarcation of land ownership.

2. Construction Layout: EDM is indispensable in construction projects. Surveyors use it to precisely mark the positions of structures, foundations, and utilities. This ensures that buildings and infrastructure are constructed according to design specifications.

3. Topographic Mapping: EDM instruments are vital for creating detailed topographic maps. Surveyors measure distances and elevations across large areas to produce accurate representations of the Earth’s surface. These maps are essential for land development, urban planning, and environmental studies.

4. Geological Surveys: Geologists use EDM to collect data in rugged and remote terrain. It helps in measuring geological features, fault lines, and rock formations accurately, aiding in geological research and resource exploration.

5. Engineering Surveys: Engineers rely on EDM for site assessments, as-built surveys, and structural deformation monitoring. It ensures that engineering projects are executed precisely and safely.

6. Mining Surveys: In the mining industry, EDM is used for tasks such as pit design, stockpile volume calculations, and monitoring subsidence. It helps optimize mining operations and ensures safety underground.

7. Hydrographic Surveys: EDM technology is employed in hydrographic surveys to measure distances between vessels and shorelines or underwater features. This data is crucial for navigation, coastal engineering, and marine resource management.

8. Utility Mapping: Surveyors use EDM to map underground utilities such as water, gas, and sewer lines. Accurate measurements are essential for avoiding utility clashes during construction projects.

9. Bridge and Tunnel Surveys: EDM is instrumental in bridge and tunnel inspections, helping engineers assess structural integrity and detect deformations or shifts over time.

10. Archaeological Excavations: – Archaeologists use EDM to measure and document archaeological sites, artifact locations, and excavation grids accurately. It aids in preserving historical and cultural heritage.

11. Forestry and Environmental Surveys: – EDM technology is utilized in forestry for tree height measurements and in environmental studies to monitor ecological changes and habitat mapping.

12. Remote Sensing: – Some EDM instruments can be mounted on aircraft or drones to collect data from remote or inaccessible areas. This is valuable for aerial surveys and monitoring large land areas quickly.

13. Geodetic Surveys: – Geodetic surveys, which determine precise positions on the Earth’s surface, heavily rely on EDM for measuring baselines and triangulation points. This data contributes to global positioning systems (GPS) and geospatial databases.

14. Structural Monitoring: – EDM is used to monitor the movements and deformations of structures such as bridges, dams, and buildings. Real-time data helps ensure structural safety.

15. Mine Safety: – In mining operations, EDM technology can be used to monitor the stability of tunnels and prevent accidents due to collapses.

16. Environmental Monitoring: – EDM is employed to monitor coastal erosion, glacier movement, and other environmental changes over time.

EDM Survey software

Electronic Distance Measurement (EDM) survey software plays a crucial role in modern surveying and geospatial data collection. These software applications are designed to work seamlessly with EDM instruments and provide surveyors with the tools they need to efficiently gather, process, and analyze survey data. Here are some popular EDM survey software options:

Trimble Access:

- Trimble Access is a comprehensive surveying software solution that supports a wide range of Trimble EDM instruments. It offers a user-friendly interface, data management capabilities, and a suite of surveying apps for field and office use. Trimble Access facilitates real-time data transfer between the field and office, enhancing productivity.

Leica Infinity:

- Leica Infinity is designed to work with Leica Geosystems’ EDM instruments. It offers data processing and management tools, including 3D visualization, volume calculations, and advanced coordinate transformations. The software streamlines data flow from the field to the office.

Topcon Magnet Field and Office:

- Topcon’s Magnet software suite includes both field and office solutions. Magnet Field provides surveyors with intuitive data collection tools, while Magnet Office offers data processing, CAD drafting, and reporting capabilities. The software is compatible with various EDM devices from Topcon.

Carlson SurvCE and Carlson Survey:

- Carlson Software offers SurvCE for field data collection and Carlson Survey for office-based surveying tasks. These software packages support a wide range of EDM instruments and provide tools for topographic mapping, construction layout, and data analysis.

Sokkia GeoPro Office and Field:

- Sokkia’s GeoPro software solutions cater to both field and office needs. GeoPro Field is designed for data collection and stakeout tasks, while GeoPro Office offers data processing, analysis, and reporting capabilities. Sokkia’s software is compatible with their EDM instruments.

GeoMax X-PAD Survey:

- GeoMax’s X-PAD Survey software is user-friendly and compatible with various EDM devices. It offers comprehensive surveying and stakeout features, allowing surveyors to efficiently collect and process data in the field and office.

South Surveying & Mapping Software:

- South Surveying & Mapping offers a range of software solutions that work with their EDM instruments. These include data collection software for field use and data processing software for the office.

MicroSurvey FieldGenius and STAR*NET:

- MicroSurvey’s FieldGenius is a field data collection software compatible with various EDM instruments. STAR*NET, on the other hand, is a software package for survey data adjustment and network adjustment.

Open Source Solutions:

- There are open-source surveying software options available, such as JAG3D and GRASS GIS (Geographic Resources Analysis Support System), which can be used in combination with EDM instruments. These software solutions offer flexibility and customization but may require more technical expertise to implement effectively.

What are the best practices for EDM surveying?

Here are some valuable tips for conducting Electronic Distance Measurement (EDM) surveys effectively:

1. Choose the Right EDM Instrument: Select an EDM instrument that suits the specific requirements of your survey. Consider factors like measurement range, accuracy, and environmental conditions at the survey site.

2. Check Calibration: Ensure that your EDM instrument is properly calibrated before starting any measurements. Regular calibration helps maintain measurement accuracy.

3. Environmental Factors: Be aware of environmental factors such as temperature, humidity, and air pressure, as they can affect the speed of the signal. Use instruments equipped with environmental sensors and make necessary adjustments.

4. Reflective Targets: When conducting EDM surveys, use reflective targets, such as prisms, to enhance signal reflection. Properly maintained and clean targets improve measurement accuracy.

5. Line of Sight: Maintain a clear line of sight between the EDM instrument and the target. Obstructions like trees, buildings, and hills can disrupt signals and compromise accuracy.

6. Stay Level: Ensure that the instrument and the target are positioned on level ground. Survey on uneven terrain may introduce measurement errors.

7. Field Procedures: Follow established field procedures, including proper setup, leveling, and alignment of the instrument. Accurate measurements start with correct instrument positioning.

8. Data Recording: Record measurement data systematically and accurately. Keep clear notes and labels to identify measurement points and conditions.

9. Multiple Measurements: Take multiple measurements from different positions or angles to improve accuracy. Calculate an average or use triangulation for more precise results.

10. Data Quality Control: – Regularly check your measurement data for consistency and outliers. Identifying and addressing errors early in the survey process can save time and resources.

11. Data Management Software: – Use dedicated EDM survey software for data collection and processing. These tools streamline data handling and reduce the risk of errors during data transfer.

12. Real-Time Feedback: – Some EDM instruments provide real-time feedback on measurements. Use this feature to quickly identify and correct errors in the field.

13. Safety Measures: – Prioritize safety during surveying activities. Be cautious when working near roadways, cliffs, or other potentially hazardous areas.

14. Documentation: – Maintain detailed documentation of your survey, including field notes, sketches, and instrument settings. This documentation is essential for quality control and future reference.

15. Quality Assurance: – Implement quality assurance procedures to validate the accuracy and reliability of your measurements. This may involve cross-checking with other survey methods or known reference points.

16. Post-Processing: – After collecting data in the field, perform post-processing and data adjustment as needed. This step can refine your measurements and ensure their accuracy.

17. Training and Education: – Continuously update your knowledge and skills related to EDM surveying. Attend training sessions and stay informed about advancements in surveying technology.

18. Collaboration: – Collaborate with other surveyors or professionals in related fields to gain insights and validate your measurements, especially for complex projects.

19. Maintenance: – Regularly maintain and calibrate your EDM instrument to ensure it operates at its optimal performance level.

20. Legal Considerations: – Be aware of local surveying regulations and legal requirements. Ensure that your surveys comply with all applicable laws and standards.

What are the disadvantages of EDM?

Electronic Distance Measurement (EDM) is a valuable technology in surveying and related fields, but it does come with some disadvantages and limitations. Here are the key disadvantages of EDM:

Line of Sight Required:

- EDM measurements require an unobstructed line of sight between the instrument and the target. Obstacles like buildings, vegetation, and terrain features can hinder measurements, limiting its usability in certain environments.

Limited in Adverse Weather:

- Adverse weather conditions, such as heavy rain, fog, or snow, can disrupt the signal used in EDM, reducing its accuracy and range. This limitation can impact surveying operations in regions with unpredictable weather.

Signal Absorption:

- In some cases, the signal emitted by EDM instruments can be absorbed or weakened when passing through certain materials or substances, making it less effective in specific surveying scenarios.

Accuracy Affected by Environmental Factors:

- EDM accuracy can be influenced by environmental factors like temperature, humidity, and air pressure. Changes in these conditions may require adjustments to maintain measurement precision.

Limited Range for Some Instruments:

- While many EDM instruments offer impressive measurement ranges, some may have limitations, particularly in extreme long-distance measurements. In such cases, alternative surveying methods may be necessary.

Complex Setup and Calibration:

- Properly setting up and calibrating EDM instruments can be complex and time-consuming. Surveyors need to ensure that the instrument is level, aligned correctly, and adequately calibrated to obtain accurate measurements.

Equipment Cost:

- High-quality EDM instruments can be expensive, making them a significant investment for surveying professionals and organizations. This cost can be a barrier for smaller surveying firms.

Maintenance Requirements:

- EDM instruments require regular maintenance and calibration to ensure accurate measurements. Failing to maintain the equipment can result in measurement errors and reduced performance.

Limited Use in Non-Visible Areas:

- EDM is primarily suited for measurements with a direct line of sight. It may not be suitable for surveying tasks in areas where targets are not visible, such as underground or within buildings.

Data Processing Complexity:

- Processing and analyzing data collected using EDM instruments can be complex and may require specialized software. Surveyors need to have the necessary skills to handle and interpret the data effectively.

Safety Concerns:

- In some situations, surveyors may need to work near roadways or in potentially hazardous environments to establish a line of sight. Safety precautions are essential to mitigate risks.

Limited Accuracy for Very Long Distances:

- While EDM provides high accuracy for most surveying tasks, extremely long-distance measurements (over several kilometers) may have reduced accuracy due to factors like atmospheric refraction.

Interference from Electronic Devices:

- Electronic devices and electromagnetic interference can disrupt EDM signals. Surveyors must be mindful of sources of interference when conducting measurements in urban or industrial areas.

What are the common errors in EDM surveying?

Electronic Distance Measurement (EDM) surveying is a precise technique, but like any measurement process, it can be prone to errors. To ensure accurate results, it’s essential to be aware of common errors and take steps to mitigate them. Here are some common errors in EDM surveying:

Instrumental Errors:

- Calibration Errors: Failure to calibrate the EDM instrument regularly can introduce systematic errors. Calibration ensures that the instrument provides accurate measurements.

- Instrument Drift: EDM instruments may experience gradual changes in their measurement characteristics over time, resulting in drift errors. Regular maintenance and recalibration can help mitigate this issue.

Environmental Factors:

- Atmospheric Conditions: Variations in temperature, humidity, and air pressure can affect the speed of the signal used in EDM. Modern instruments often compensate for these factors, but rapid changes in weather conditions can still introduce errors.

- Air Turbulence: Turbulent air caused by wind or temperature gradients can distort the path of the signal, leading to measurement errors.

- Refraction: Atmospheric refraction can cause signal bending, particularly over long distances, resulting in inaccurate measurements.

Instrument Setup Errors:

- Leveling and Alignment: Incorrect instrument leveling and alignment can introduce angular errors. Ensuring that the instrument is level and aligned correctly is crucial for accurate measurements.

- Target Placement: Inaccurate placement of reflective targets (prisms) or their misalignment with the line of sight can lead to measurement errors.

Signal Obstructions:

- Obstructions in the Line of Sight: Physical obstructions such as trees, buildings, and terrain features can disrupt the line of sight between the instrument and the target, resulting in incomplete or inaccurate measurements.

Multipath Interference:

- **Multipath interference occurs when the signal reflects off unintended surfaces before reaching the target. This can lead to measurement errors, especially in urban environments with reflective surfaces like glass buildings.

Data Recording Errors:

- Mislabeling and Recording Mistakes: Inaccurate recording of measurement data, mislabeling of points, or recording data under incorrect conditions can result in measurement errors.

Human Errors:

- Misoperation: Surveyors may make operational mistakes, such as selecting incorrect settings on the instrument or failing to account for environmental factors.

- Data Entry Errors: Errors can occur during data entry when transferring measurement data from the field to processing software or records.

Limited Measurement Range:

- Some EDM instruments have limitations in their measurement range. Attempting measurements beyond the instrument’s capabilities can lead to inaccuracies.

Poor Visibility:

- Low visibility conditions due to fog, rain, or dust can reduce the instrument’s ability to establish a clear line of sight with the target.

Software and Data Processing Errors:

- Errors can occur during data processing, including incorrect coordinate transformations, software glitches, or inaccurate adjustment methods.

How to avoid errors in EDM surveying?

Avoiding errors in Electronic Distance Measurement (EDM) surveying is crucial to ensuring accurate and reliable measurements. Here are essential steps and strategies to minimize errors in EDM surveying:

Regular Calibration and Maintenance:

- Schedule routine calibration and maintenance of your EDM instrument as per the manufacturer’s recommendations. Properly calibrated instruments are less likely to introduce systematic errors.

Environmental Monitoring:

- Continuously monitor environmental conditions such as temperature, humidity, and air pressure during your survey. Many modern EDM instruments are equipped with environmental sensors to aid in compensation.

Choose Optimal Weather Conditions:

- Whenever possible, conduct surveys in favorable weather conditions with minimal atmospheric disturbances. Avoid surveys during heavy rain, fog, or extreme temperature fluctuations.

Instrument Setup and Alignment:

- Ensure that your EDM instrument is set up correctly, level, and aligned accurately with the target. Proper leveling and alignment are essential for minimizing angular errors.

Use High-Quality Reflective Targets:

- Employ high-quality, well-maintained reflective targets (prisms) that are clean and correctly positioned. Check for any defects or misalignments in the prisms.

Clear Line of Sight:

- Verify and maintain a clear line of sight between the instrument and the target. Remove obstructions such as vegetation, structures, or debris that could disrupt the signal.

Multipath Interference Prevention:

- Minimize multipath interference by choosing survey locations with minimal reflective surfaces and ensuring that targets are positioned to minimize signal reflections.

Instrument Operation:

- Operate the EDM instrument according to the manufacturer’s guidelines. Avoid overloading the instrument with excessive measurements or using it in ways that could lead to overheating.

Data Verification and Validation:

- Implement robust quality control procedures to verify and validate measurement data in real-time. Cross-check measurements, identify outliers, and correct errors promptly.

Data Recording Accuracy:

- Record measurement data accurately and consistently. Double-check labels, notes, and any annotations to ensure that data is correctly associated with each measurement point.

Post-Processing and Data Adjustment:

- After data collection, perform thorough post-processing and data adjustment using reliable software. Ensure that coordinate transformations and adjustments are accurate.

Training and Skill Development:

- Invest in training and skill development for surveyors to enhance their knowledge of EDM instruments and surveying techniques. Knowledgeable surveyors are less likely to make operational errors.

Documentation:

- Maintain comprehensive records of the survey, including field notes, sketches, and instrument settings. Detailed documentation assists in error identification and correction.

Data Backups:

- Regularly back up all measurement data to prevent data loss due to equipment malfunctions or software issues.

Collaboration and Peer Review:

- Collaborate with other experienced surveyors or professionals for complex projects. Peer review can help identify errors and provide valuable insights.

Compliance with Standards and Regulations:

- Ensure that your surveying activities comply with local surveying standards and regulations. Familiarize yourself with legal requirements in your region.

Continuous Improvement:

- Encourage a culture of continuous improvement within your surveying team. Regularly review procedures and processes to identify areas where errors can be minimized.

By following these steps and practicing diligent surveying techniques, you can significantly reduce errors in EDM surveying and achieve more accurate and reliable measurement results.

Conclusion:

Electronic Distance Measurement is a remarkable technology that has revolutionized the fields of surveying and construction. By harnessing the speed of light or electromagnetic waves and accurately measuring time, EDM instruments provide surveyors with the precise distance data they need to carry out their work with unparalleled accuracy and efficiency.

Key Takeaways

- EDM technology offers enhanced accuracy, faster measurement, and improved safety compared to traditional methods.

- Choosing the right EDM device depends on factors like measurement range, accuracy, and environmental conditions.

- Regular calibration and servicing are essential for maintaining the accuracy of EDM devices.