No — standard cement cannot be used as a proper self-leveling compound.

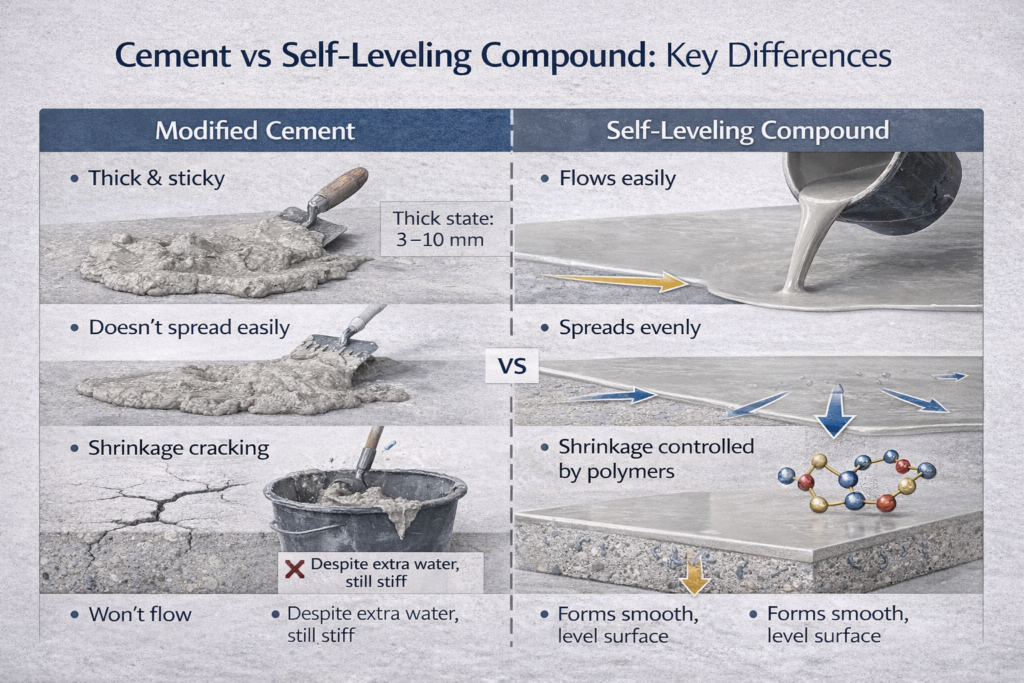

Cement alone does not flow, spread, or level itself the way true self-leveling underlayment does. It lacks the polymers, flow agents, and precise grading that allow professional floor leveling compounds to create a smooth, flat surface without troweling.

Here’s what happens if you try:

- It will not self-spread evenly

- It may shrink and crack while curing

- Surface will likely be rough and uneven

- Poor bonding can cause delamination

- Floor coverings may fail prematurely

Self-leveling compounds are engineered blends of cement, fine aggregates, polymers, and additives designed to flow like pancake batter and harden into a smooth surface. Regular cement is only one ingredient in that system — not the finished solution.

If you need to fix dips, slopes, or surface imperfections before installing tile, vinyl, hardwood, or epoxy, using plain cement is a shortcut that often leads to expensive repairs.

Let’s explore it further below.

What Is Self-Leveling Compound and How Does It Actually Work?

Self-leveling compound (SLC) is a specialized cement-based underlayment engineered to flow and settle into a flat surface with minimal manual finishing. It is not just “thin cement.” It is a chemically modified system.

A true self-leveling mix contains:

| Component | Purpose |

|---|---|

| Portland cement | Structural binder |

| Fine aggregates | Smooth finish |

| Polymers | Flexibility & bonding |

| Flow agents | Improve spreadability |

| Retarders | Controlled working time |

| Defoamers | Prevent air bubbles |

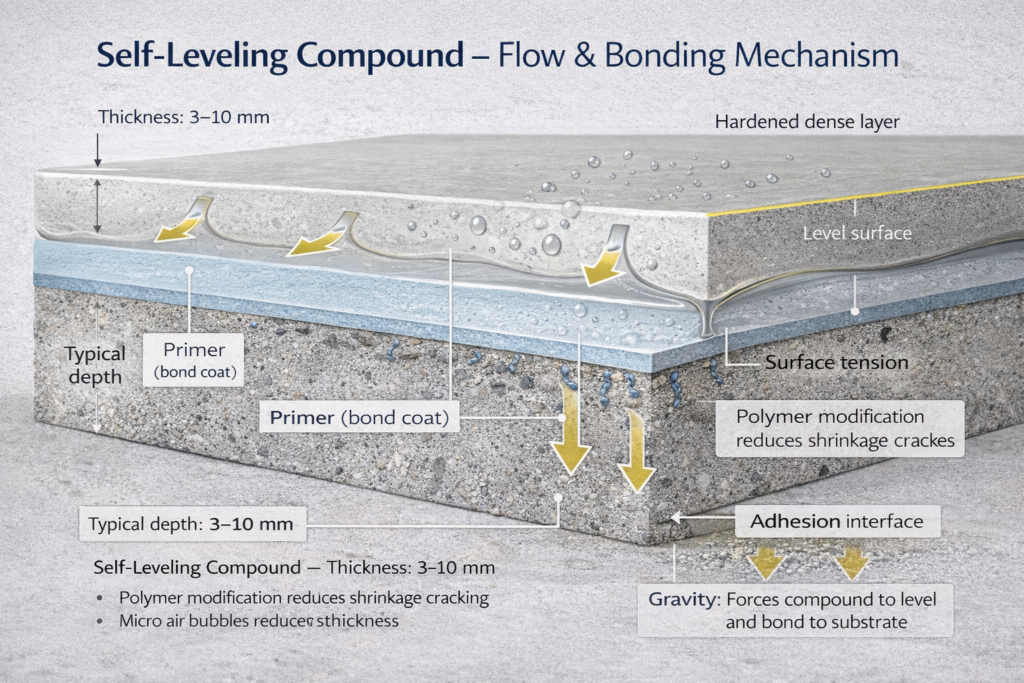

When mixed with water in the correct ratio, it behaves like a thick liquid. Gravity does most of the leveling work. As it cures, it hardens into a dense, smooth layer ready for flooring installation.

Plain cement lacks:

- Flow modifiers

- Shrinkage control agents

- Adhesion promoters

- Surface tension reducers

Without these, cement behaves like stiff mortar, not a leveling fluid.

Professionals use SLC when preparing floors for:

- Porcelain or ceramic tile

- Luxury vinyl planks (LVP)

- Engineered hardwood

- Polished concrete overlays

- Epoxy coatings

Modern self-leveling compounds can achieve flatness tolerances within 1/8 inch over 10 feet — a requirement for many floating floor systems.

If you attempt to use cement alone, you will need heavy manual screeding, constant checking with a level, and still may not achieve acceptable flatness.

Why Cement Does NOT Self-Level (The Material Science Behind It)

Cement is a binder. It reacts chemically with water through hydration to form calcium silicate hydrates — the glue that gives concrete strength.

But cement does not flow by itself.

Here’s why:

1. High Viscosity

Cement paste has thick consistency. Even when mixed with water, it does not naturally flatten under gravity.

2. No Surface Tension Control

Self-leveling products contain additives that reduce surface tension, allowing the mix to spread smoothly. Cement lacks this.

3. Shrinkage Behavior

Cement shrinks as it cures. Without proper additives, shrinkage leads to:

- Hairline cracks

- Curling edges

- Debonding

4. Poor Flexural Strength

Standard cement paste is brittle. SLC includes polymers that improve flexibility, reducing cracking under minor slab movement.

A thin cement layer less than 10 mm thick is highly prone to cracking unless modified with polymers or fibers.

When you pour cement hoping it will “find its own level,” it simply won’t. It stiffens quickly and locks in irregularities.

What Happens If You Try Using Cement Instead?

Let’s be practical.

Imagine you have a concrete slab with dips and low spots. You mix cement and water and pour it in. Here’s what typically happens:

- It pools unevenly.

- Thick areas stay high.

- Thin edges dry too fast.

- Surface becomes rough and patchy.

- Cracks appear within days.

Common Real-World Failures

- Tile cracking due to hollow spots

- Vinyl flooring showing telegraphing lines

- Engineered wood flexing over uneven substrate

- Epoxy peeling because of poor adhesion

In many renovation cases, contractors are later called to remove failed cement patches and redo the leveling with proper compound.

The cost of repair can be 3–5 times higher than using the right product initially.

Can You Modify Cement to Make It Self-Leveling?

Short answer: not reliably.

Some attempt to mix cement with:

- Extra water

- Sand

- Bonding agents

- Latex additives

While adding polymer bonding agents improves adhesion, it does not transform cement into a true self-leveling system.

Too much water weakens strength.

Too little water prevents flow.

Too much additive causes segregation.

Professional SLC products are lab-tested for:

- Flow spread (ASTM C1708)

- Compressive strength

- Bond strength

- Set time control

Homemade mixes cannot replicate this precision.

Even small changes in water ratio can reduce cement strength by over 30%.

If precision floor flatness matters — and it usually does — modifying cement is risky.

When (If Ever) Can Cement Be Used for Leveling?

There are situations where cement-based materials can help with leveling — but not as a self-leveling product poured directly from a bucket.

Cement can be used in:

- Thick screed layers (40–75 mm)

- Bonded mortar beds

- Hand-troweled patch repairs

- Slope corrections in wet areas

- Outdoor slab grading

The key difference is application method.

Instead of relying on gravity to do the work, these systems require:

- Screed guides

- Straightedges

- Laser levels

- Skilled finishing

Cement Screed vs. Self-Leveling Compound

| Feature | Cement Screed | Self-Leveling Compound |

|---|---|---|

| Application | Manual screeding | Poured & spread |

| Thickness | 40 mm+ typical | 3–10 mm typical |

| Skill level | High | Moderate |

| Surface finish | Rough to medium | Smooth |

| Crack resistance | Moderate | High (polymer-modified) |

| Dry time | Slower | Faster |

Cement screeds are commonly used in large commercial projects and new construction. They are not the same as pouring a thin layer of cement expecting it to level itself.

Traditional sand-cement screeds have been used for centuries, but modern polymer-modified leveling compounds can reach walkable strength in as little as 4 hours.

If you’re correcting major slope differences (over 1 inch), a properly installed bonded cement screed can work. But for thin floor preparation before tile or vinyl? Self-leveling compound is safer and more precise.

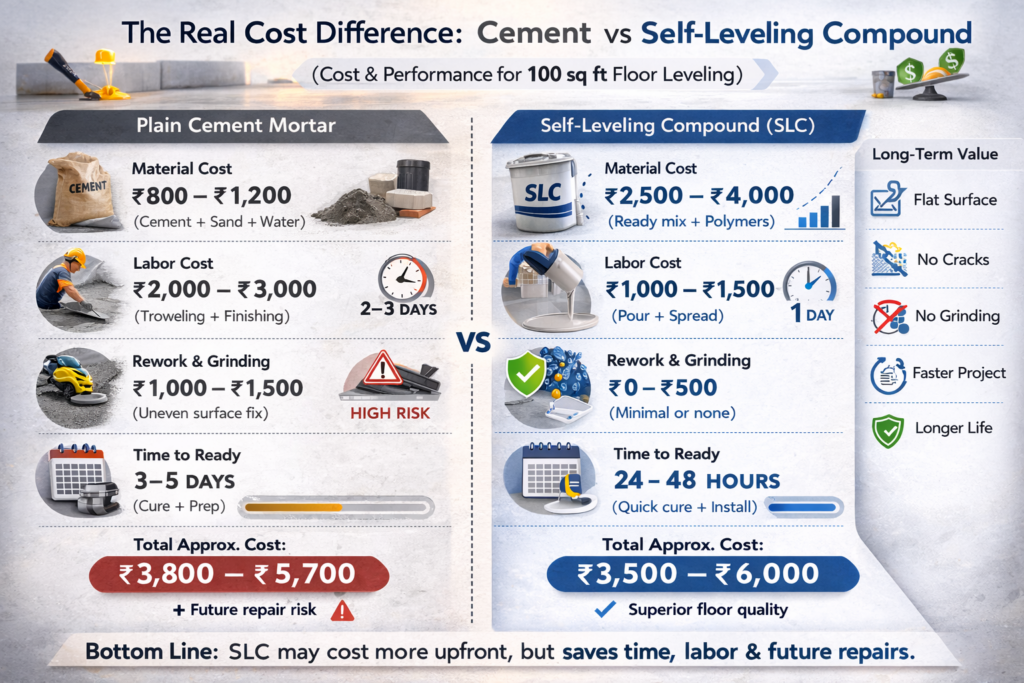

The Real Cost Difference: Cement vs Self-Leveling Compound

Many people consider cement because it seems cheaper.

Let’s break it down realistically.

Material Cost Comparison (Approximate)

| Material | Cost per 50 lb bag | Coverage (at 1/8″) |

|---|---|---|

| Cement | Low | Not suitable |

| Sand + Cement Mix | Low | Limited |

| Self-Leveling Compound | Higher | Designed for thin leveling |

Yes, self-leveling compound costs more per bag.

But here’s what people miss:

Hidden Costs of Using Cement

- Extra labor time

- Multiple passes

- Surface grinding

- Crack repairs

- Flooring failure

- Removal and redo

In real-world renovation projects, failed leveling jobs often cost several times more than simply using proper SLC from the start.

When you factor:

- Time

- Precision

- Floor finish durability

- Warranty protection

Self-leveling compound becomes cost-effective.

How Professionals Level Floors Correctly

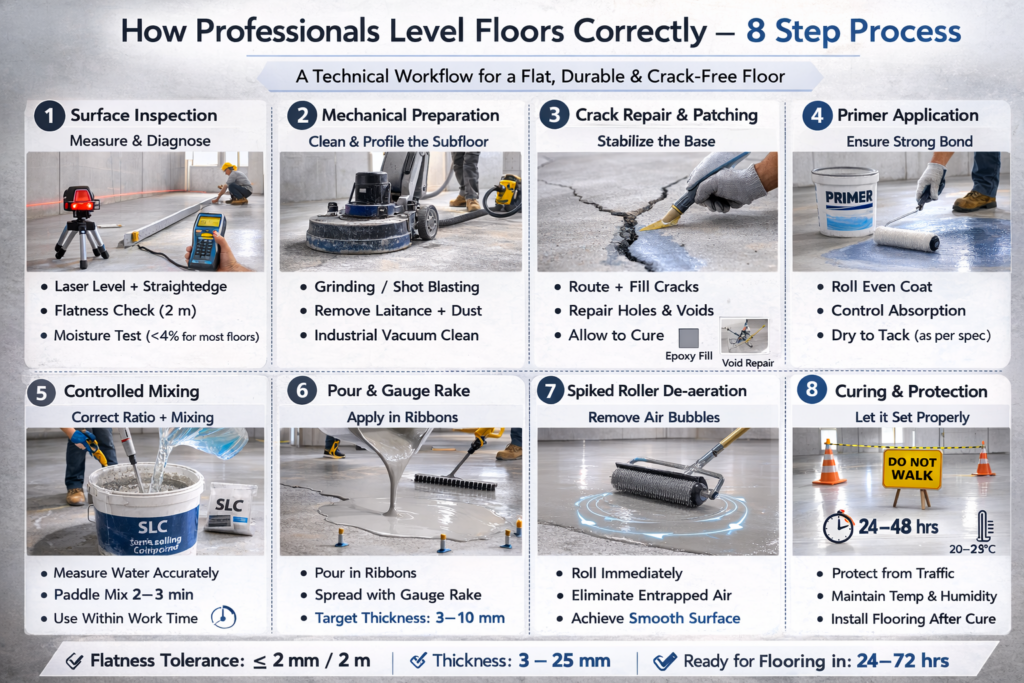

Professional installers follow a strict preparation process.

Step 1: Surface Inspection

They check:

- Flatness tolerance

- Moisture content

- Structural cracks

- Soundness of substrate

Step 2: Surface Preparation

- Grinding high spots

- Cleaning debris

- Applying primer

Primer is critical. It improves bonding and prevents rapid moisture loss.

Step 3: Mixing Ratio Control

Self-leveling compound must be mixed exactly to manufacturer specification. Too much water weakens it. Too little reduces flow.

Step 4: Controlled Pour

- Pour in ribbons

- Spread lightly with gauge rake

- Use spike roller to release air bubbles

Step 5: Cure & Protect

Most SLC systems allow tile installation within 16–24 hours, depending on thickness.

Floor flatness standards for many floating floor systems require no more than 3 mm variation over 3 meters. Cement paste alone rarely achieves this tolerance.

Professional installers rarely attempt thin leveling using plain cement because consistency cannot be guaranteed.

Better Alternatives If You Don’t Want Full Self-Leveling Compound

If cost is a concern, consider these safer alternatives instead of plain cement:

1. Cement-Based Floor Patching Compound

Designed for small dips and cracks. Trowel-applied but polymer-modified.

2. Feather Finish Products

Used for thin smoothing layers before vinyl installation.

3. Dry Pack Mortar (For Thick Builds)

Used when leveling thick sections over stable substrate.

4. Gypsum-Based Leveling Compounds

Used in interior dry spaces where rapid curing is needed.

Each of these products is engineered for specific thickness and bonding conditions. Plain cement is not.

Many modern vinyl flooring warranties become void if installed over improperly leveled substrates.

Choosing the right underlayment protects not just the slab — but your finished floor investment.

Common Mistakes to Avoid

Using cement as a substitute for self-leveling compound often leads to preventable failures. Here are the most common mistakes that cause costly problems:

1. Adding Extra Water to Improve Flow

Many DIYers think adding more water will make cement self-level. It will flow more — but at a cost.

Excess water:

- Weakens compressive strength

- Increases shrinkage

- Causes surface dusting

- Leads to cracking

A thin, watery cement mix may look smooth at first but becomes brittle after curing.

2. Skipping Primer on Concrete Substrate

Unprimed surfaces absorb water rapidly from cement mixes. This causes:

- Poor bonding

- Curling edges

- Surface cracks

Self-leveling systems require primers for a reason. Cement without primer is high risk.

3. Attempting Thin Applications (Under 10 mm)

Cement-based mixes are not designed for ultra-thin leveling layers. Thin sections dry too quickly and crack easily.

Thin leveling requires polymer modification — which plain cement does not provide.

4. Ignoring Floor Flatness Standards

Modern flooring systems demand strict tolerances. Without checking flatness using straightedges or laser levels, uneven spots remain hidden until final flooring is installed.

By then, repair costs multiply.

5. Not Controlling Curing Conditions

Cement reacts chemically with water. Rapid drying from:

- Direct sunlight

- Wind exposure

- High indoor heat

can cause shrinkage cracking.

Uneven curing is one of the leading causes of microcracks in thin cement layers, even when the mix ratio is correct.

Avoiding these mistakes alone can save thousands in rework.

Expert Tips to Remember

If leveling a floor is part of your project, keep these professional insights in mind:

1. Flat Is More Important Than Level

For most flooring systems, perfectly horizontal isn’t required — but flatness is critical. Focus on eliminating dips and humps.

2. Measure Before You Mix

Use a 10-foot straightedge or laser level to map high and low areas. Knowing the maximum deviation determines the right product.

3. Respect Thickness Limits

Every leveling product has minimum and maximum thickness requirements. Never guess.

4. Don’t Rush Set Time

Self-leveling compounds may look dry quickly but need proper curing before installing flooring. Follow recommended timelines strictly.

5. Test a Small Area First

If unsure, perform a small patch test before committing to a full pour. It reveals bonding and curing behavior early.

Many professional installers calculate material quantity using surface mapping grids to avoid cold joints and incomplete coverage.

Precision is what separates a smooth, durable floor from one that fails within months.

FAQs

1. Can I pour straight cement on concrete to level it?

No. Cement alone does not contain the additives required for proper self-leveling behavior. It will not spread evenly and may crack.

2. What is the difference between cement and self-leveling compound?

Cement is a binder. Self-leveling compound is a modified blend that includes cement, polymers, flow agents, and fine aggregates designed to create smooth surfaces.

3. Will cement stick to old concrete?

It may bond initially, but without proper surface preparation and primer, adhesion failure is common.

4. Can I mix cement with bonding agent to make it self-leveling?

Bonding agents improve adhesion but do not provide flow control or shrinkage resistance like true self-leveling formulations.

5. Is self-leveling compound waterproof?

Most cement-based leveling compounds are moisture-resistant but not waterproof membranes. Separate waterproofing may be required.

6. How thick can self-leveling compound be applied?

It depends on the product. Many allow 3–10 mm per layer, while some high-build options allow thicker pours.

7. Why did my cement leveling crack?

Common causes include excessive water, thin application, rapid drying, or lack of bonding agent.

8. Is sand-cement mix better than plain cement?

It improves bulk strength for thicker screeds but still does not create true self-leveling behavior.

9. Can I install tile over cement leveling?

Only if the surface is flat, well-bonded, and crack-free. Otherwise, tile may fail.

10. Is it cheaper to use cement instead of leveling compound?

Material cost is lower, but long-term repair risks make it more expensive in many cases.

Conclusion

Using cement as a self-leveling solution is a shortcut that often leads to failure.

Cement lacks the engineered additives required for proper flow, adhesion, shrinkage control, and crack resistance. While it can be used in thick screeds or manual leveling systems, it is not designed to function as a thin, self-leveling underlayment.

When floor flatness matters — and it almost always does — using the correct leveling compound protects your finished flooring investment.

Trying to save on material cost often leads to higher labor, rework, and replacement expenses.

The right product the first time prevents problems later.

Key Takeaways

- Cement alone does not self-level effectively.

- Self-leveling compounds contain polymers and flow agents.

- Thin cement layers are highly prone to cracking.

- Proper floor preparation prevents flooring failure.

- Using the correct underlayment saves long-term cost.

If your goal is a smooth, durable floor surface, cement by itself is not the answ